🌿 Introduction: The Shift Toward Sustainable Straws

As more and more people understand that plastic pollution is a problem, governments, brands, and consumers are demanding sustainability. Biodegradable drinking straws made from PLA (polylactic acid), PHA, and PBS have gained considerable traction.

As a result, companies that want to get into or grow their share of the eco-packaging market must invest in the right production equipment. Choosing the right biodegradable straw making machine is no longer just an option. It’s a strategic decision that will impact your product quality, production output, and your ability to compete in the market.

This guide provides you with everything you need to know about biodegradable straw machines and how to choose the right one for your business.

Biodegradable straws are made from plant-based polymers that will decompose naturally (under industrial composting conditions).

The most common materials include

• PLA (Polylactic acid): Made from either cornstarch or sugarcane. It’s an incredibly popular material because it’s affordable and easy to extrude.

• PHA (Polyhydroxyalkanoates): Fully biodegradable and marine safe. The largest hindrance is that it’s expensive.

The material is extruded into thin tubes through precise heat and pressure control to ensure consistent diameter, strength, and flexibility.

✅ Note: PLA is the most commonly used biodegradable straw material because it provides a good balance of cost, performance, and machine compatibility.

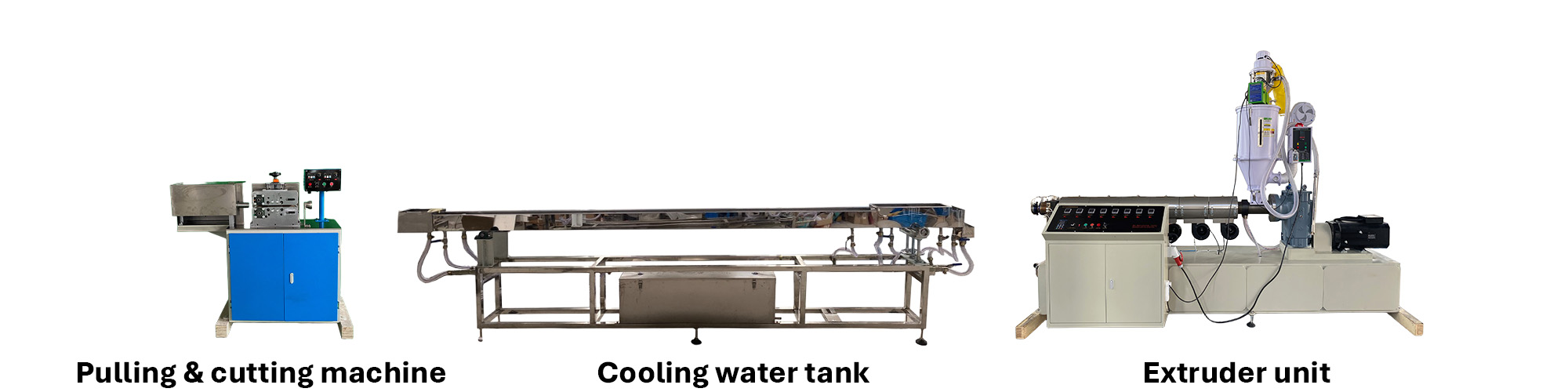

This is the most common setup for producing biodegradable straws.

Typical Components:

These machines are compatible with PLA, PP, and similar biodegradable materials.

Uses food-grade paper and glue to wind and cut straws. Ideal for markets focused on paper-based compostable packaging.

|

🧠 Choose your machine type based on material preference, market trends, and budget.

|

👉 Request a Free Quote or Demo

Not all machines are created equal, and this is how to evaluate multiple quotes:

- Configuration details: What’s the screw size (50mm, 65mm)? What brand inverter, cutter, etc.?

- Performance vs. power: You want higher output with lower energy usage.

- After-sale support: Will they help you install the machine remotely? Will they custom-make molds for you? Will they provide spare parts support?

- Verification: Get a test video of the machine and a certificate of conformity for each core unit.

Before you buy, it’s smart to see the machine in action:

Ask for a live demo via video call or a pre-recorded trial of your specific product material (PLA/PBS).

Share key details: daily production target, straw size, packaging preference.

Many suppliers offer free sample straw shipping after trial run—request it!

👉 Ready to test your material? Contact Us

| Item | Estimated Cost (USD) |

|---|---|

| PLA Straw Extrusion Line | $13,000–20,000 |

| Auto Loader / Dryer | $500–1,000 |

| Custom Molds | $500–1,000 |

| Straw Packing Machine | $4,000–6,000 |

| Piston Air Compressor | $1500–2,000 |

🏢 Plastic product factories

These companies have converted their traditional PP/PE lines over to PLA extrusion, using a similar workflow as before.

📦 Eco packaging exporters

To sell private-label biodegradable products while complying with various regulations in the EU, Canada, and U.S.

🧑💻 New startups and sustainable brands

To produce niche compostable and biodegradable products with specific design features and low volume.

🤝 OEM service providers

To provide a full-service straw experience for beverage brands to include straw production, branding and flexible production runs.

✅ Whether you’re a company that’s going to scale or one that is just starting out, there’s a straw machine configuration that will work for you.

Common Straw Types:

Packaging Options:

|

EU SUP Directive (since 2021)

U.S. state-level plastic bans

APAC voluntary phase-outs (Japan, Thailand, South Korea)

Starbucks, McDonald’s, Costa Coffee moving to compostable straws

Supermarkets prioritizing eco-packaging on shelves

PLA usage in straws growing 15–20% CAGR in regulated markets

ESG-aligned buyers prefer compostable sourcing partners

🔭 The earlier you act, the more market share and brand value you can secure.

Choosing the right biodegradable straw making machine is more than an equipment decision—it's a step toward sustainable growth. If you're looking for expert guidance, tailored configuration, or a free consultation—